0511 Assembly Services Electro-Technics ME

Assembly Procedure

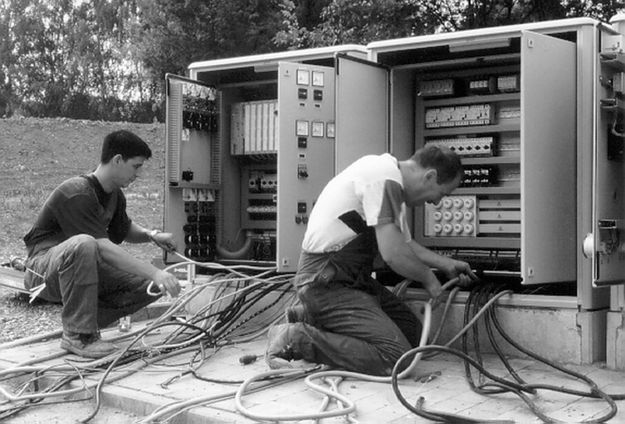

We have several assembly teams led by experienced master craftsmen. Our assembly supervisors have also qualified as sewage treatment operators. The assembly vehicles are equipped with all tools and equipment to deal with any eventualities.

Our technicians are familiar with the relevant safety regulations. The use of gas warning devices, access trestles, safety gear and other personal protective equipment is of course obligatory. Safety exercises on codes of conduct in sewers and confined space are carried out at regular intervals with our entire staff.

WHY ASSEMBLY SERVICE BY UFT?

A high degree of reliability and a long service life is expected from the electrical equipment of stormwater treatment plants of all kinds. The structure has to be ready to deal with a sudden storm at any time. All systems must work automatically without any attendant staff. The electrical equipment with measuring, control and regulation technology (I&C) is of great importance here. The operator of the plant assumes – often tacitly – a service life of the technical equipment of more than 20 years.

These high requirements must be considered in the planning and tendering phase. Careful and professional assembly, final inspection and start-up under load are the last but very important steps before handing over the system to the operator. For the reasons mentioned above, we recommend our customers to let our personnel install the devices we have supplied. This completes the chain of planning, delivery, installation and commissioning – and we can guarantee the safe functioning of our entire work.