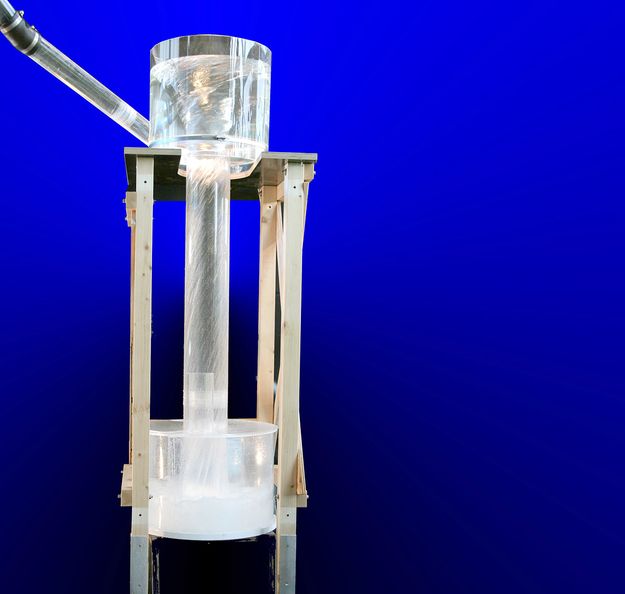

0951 Hydraulic Laboratory UFT-FluidLab

Intended Purpose

Our hydraulic laboratory has its own water circuit with a deep tank of approx. 12 m³ capacity. A speed-controlled centrifugal pump with a high-precision magnetic-inductive flowmeter (MID) extracts the water and feeds it into a distribution system. Water level sensors (pressure gauges) with various measuring ranges and data recording software are used to measure characteristic discharge curves. The results are extrapolated to prototype scale using the laws of physics.

Why Model Tests?

Today, the most common water and wastewater structures can be adequately dimensioned

with the laws of hydromechanics, if necessary also using numerical 3D flow

simulation. However, there are remaining problems that require a special solution.

Numerical computations can be expensive and time-consuming and it is questionable

how accurate and meaningful the results are, particularly where the numerical model

cannot be calibrated or where multi-phase flow computations of water, sediment and

floating matter are required. It is often cheaper, safer, more versatile and also more informative

to carry out a direct physical model test in the laboratory. All later operating

states can be simulated on the hydraulic model. Even extreme and rare discharge conditions,

e.g. catastrophic floods, can be easily investigated on the model. The designs

can be visually checked and, if necessary, improved in the planning stage by means of

model tests. The technical risk of later, expensive conversion measures can be greatly

reduced by model simulation. Finally, where extensive numerical researches are to be

carried out, these can be calibrated using model tests.